Environmentally friendly recycled leather is disrupting the traditional leather market

The alternative to traditional leather

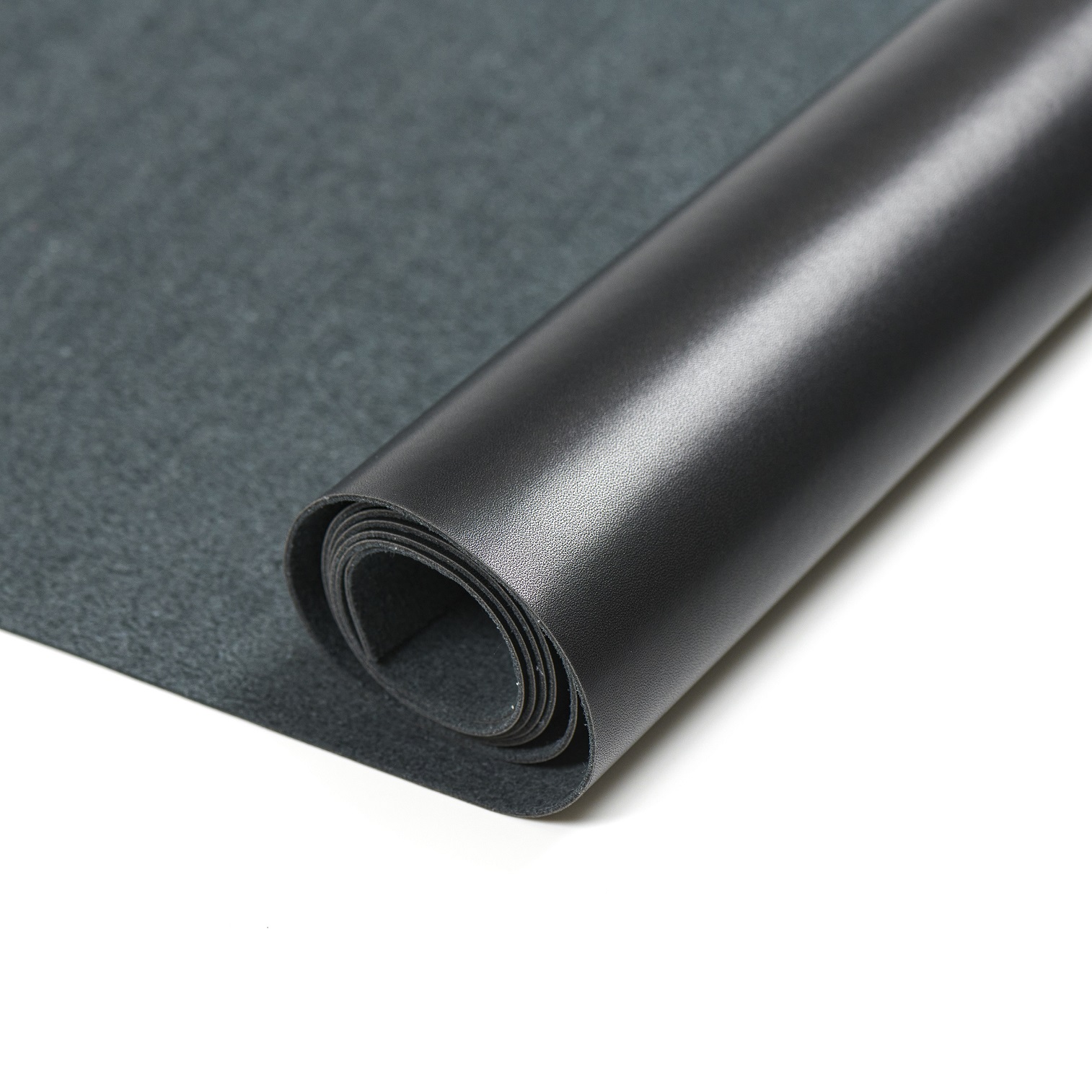

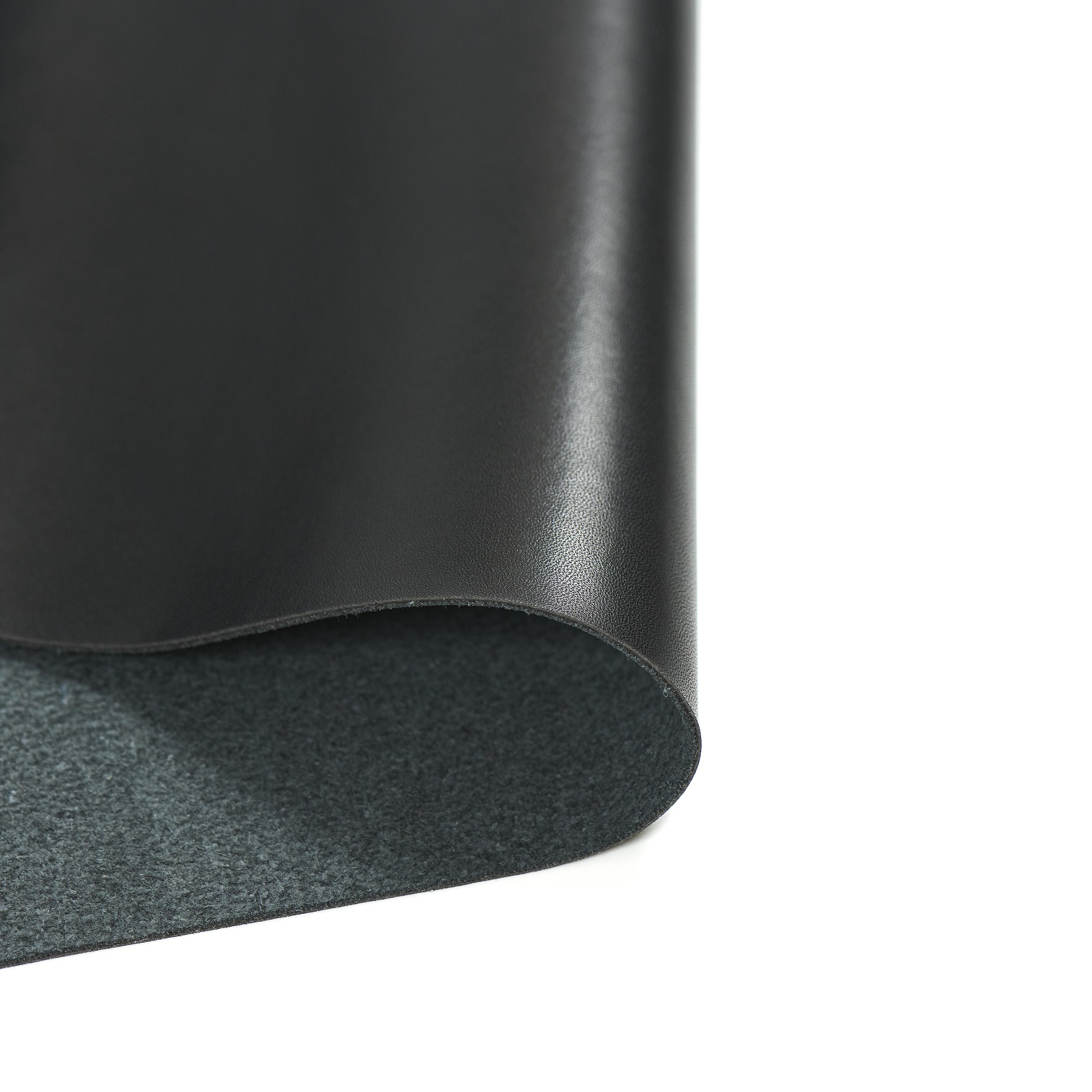

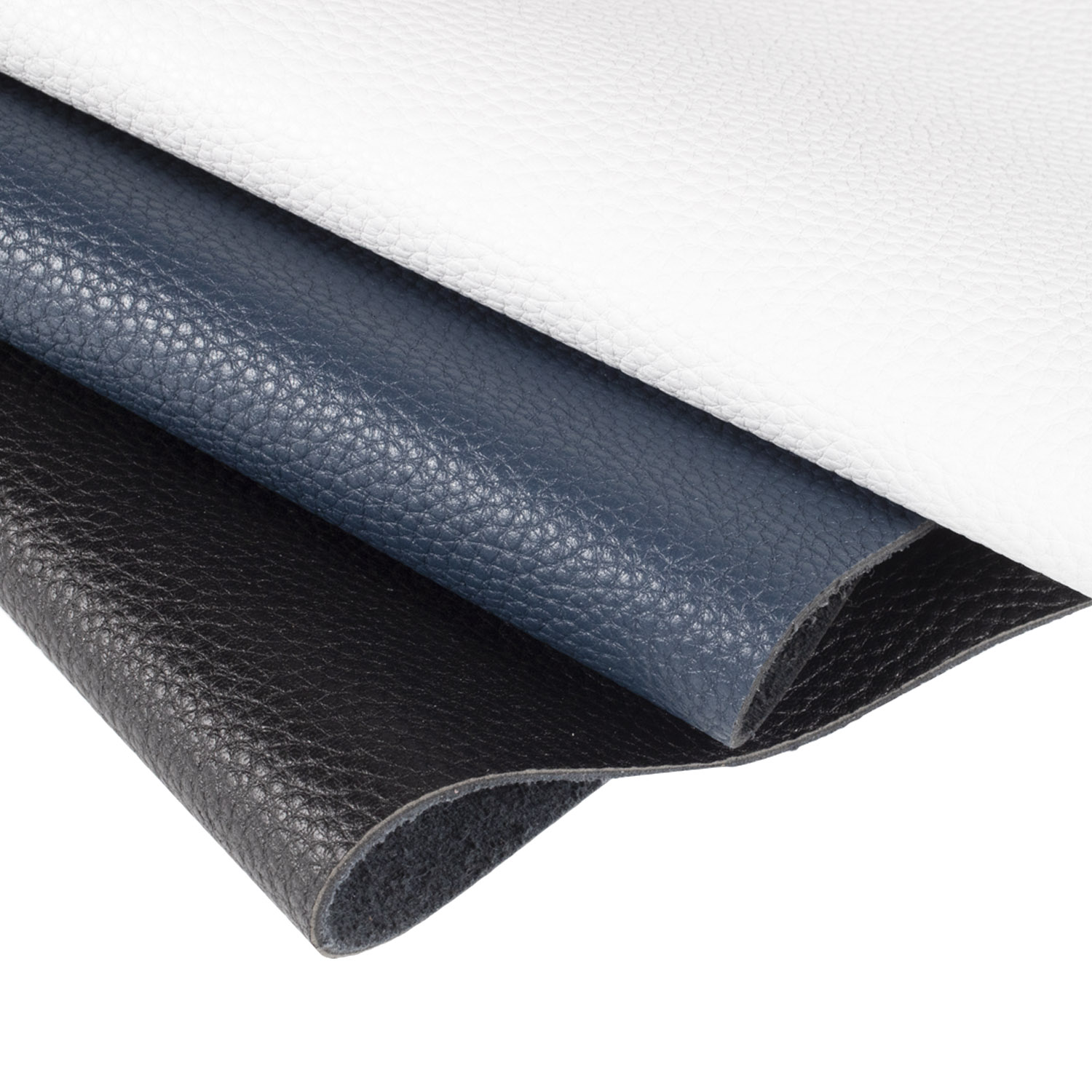

Name:Recycled Leather Thickness: 1.2-1.4mm Leather wide: 1.37meters Leather length: about 25meters each roll MOQ:300 meters each color/design . Fire retardant BS5852 CA117

- Description

- Furniture sofa leather made with natural leather fibres and water power

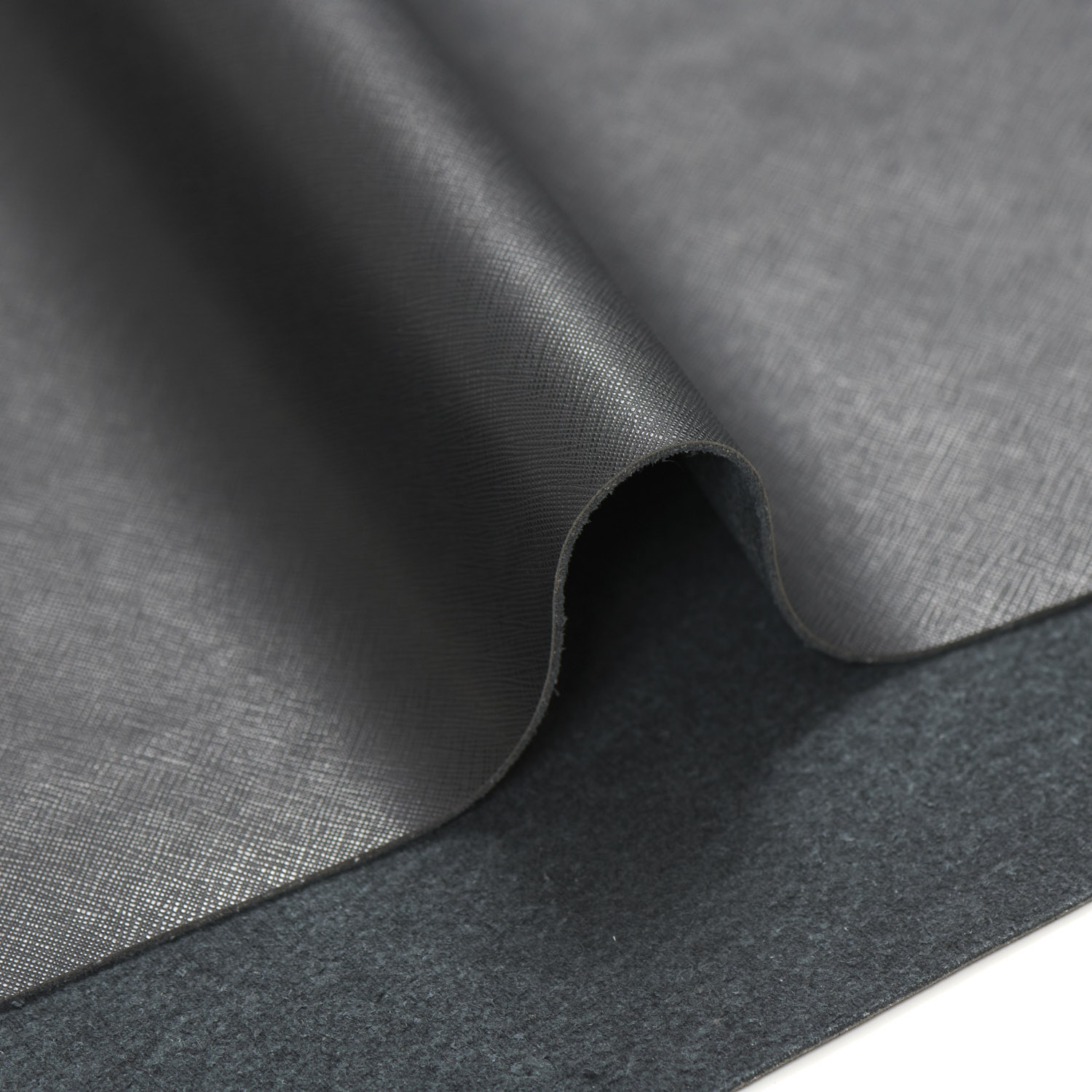

- Recycled Leather with natural leather fibers, water power and pu coating

Description

Recycled Leather

Introduction:

A wide variety of goods and excessive waste in the world now.We should reuse them and reduce waste ,rather than producing a lot of goods again. Especially in leather industry area,up to 75% of all leather hides are wasted. Therefore, a large number of leather scraps are destined for landfill,which it has a great pollution to the land and water.What`s more,there is a huge waste for the planet and the destruction of the environment entering into an infinite circle. Facing this situation,this is where recycled leather comes in.

What is recycled leather ?

Recycled leather is a bright new star in green materials,comes from ingenious transformation and upgrading of leather waste.It not only delivers the luxury and elegance of natural leather,but also sets a new benchmark in environmental protection concept.Through innovative recycling technology,the leather waste can be reborn and shine with a different brilliance.It becomes the ideal choice both fashion and environmental protection,widely used in furniture,shoes,handbags and other fields.It symbolizes the respect and cherishment of natural resources and indicates the bright future of sustainable development.

How it`s made ?

- We rescue what people call waste ,reusing it into new,long lasting and high performance recycled leather that rivals the traditional leather.

- To mill waste and separate them into soft fine fibers.

- These soft fine fibers are gently compressed into sheets of uniform fiber web.

- We use high pressure water jets technology to get the substrate produced on a roll.

- The base are coagulated in natural oil and high performance coating are added with color and texture.

Recycled Leather VS Traditional Leather

| Recycled Leather | Traditional Leather |

| Regular size about 25 meters length each roll ,width 140cm | irregular |

| Easy to cut,cost effective,no waste | more wastage ,more cost |

| Thickness ,surface color ,texture grain ,gloss are all customized,all are uniform finish | anomalous grain texture,thickness and color |

| Environmentally friendly high performance coating,more durable ,scuff and scratch resistant | less abrasion resistance |

| 50% lighter | weight disadvantages |

| Low maintenance ,high performance coating , easy to keep clean and maintain | difficult |

| Less waste ,recycle more | increasing huge waste to the landfill on the planet we live |

| Environmentally friendly | over-consumption water and pollution to the land,more carbon to make traditional leather |

| Competitive price | Expensive |

Who We Are ?

We are engineered for the end of excessive waste.

We have been giving leather waste a new life for 28 years.

We are creating what people want and what the planet deserves now.

We are the people behind the sustainable upcycled leather alternative.

We are letting our mission have true impact of industry and the planet at an epic scale now.

Elfa leather is the real pioneer of recycled leather.Our proprietary manufacturing process turns leather waste into innovative materials while achieving sustainability goals for client finished products.Elfa leather reduces waste, increases performance,enables brands to create extraordinary products and memorable customer experiences while improving sustainability.It`s leather evolved.It is an innovative material made with up to more than 50% leather fibers.It gives customers a feeling of an upgrade with a premium material that looks and feels of traditional leather.It has so many benefits that real leather lacks. Such as ,uniform texture/color,more scratch resistance,uniform size,more flexible ,easy to cut,saving labor cost.usage rate 99%,no waste to landfill,saving natural scarce resources (water &land) ,lowering carbon emissions,50%lighter,easier to keep clean.

Why need recycled leather ?

(No waste to the landfill . No over consumption of natural scarce resources water & land.) (Lowering carbon emissions ,Saving Natural resources , Increasing recycled content.)

- Up to 75% of traditional leather are wasted when we use it for products.Along with them,the natural resources (water and land) used to make them.

- Recycle more and waste less .

- Protecting our only planet we live.

——————————————————————————————————————————–

With the aggravation of environment pollution on the international agenda,coupled with a focus on limited resources and a dedication to the ethical treatment of animals,recycled leather has entered into the scene as a force for good.Now a lot of famous brands specifically have long sought sustainable materials,originally turning to fabric,now they are using recycled leather,such as Nike,Armani,NB,MLB,ASCIS etc.In the near future,there is a strong upward demand for ethical,green and recycled products to the market of our only planet we live.

Recycled Leather Experts

Made from recycled leather off-cuts, it`s the best performing, eco-friendly and economical alternative to leather on the market today. And unsurprisingly, its use is widespread and growing. Driving its worldwide success is pioneer and leading expert in the field ELFA leather.

ELFA LEATHER HAS WORLDWIDE ACCLAIM

The company operates from its production plant in Wuxi CN, where it exports its Products to Asia, United States, Europe, Taiwan, India, and internationally.Leading international brands and companies use recycled leather from ELFA Leather .

Its groundbreaking recycled leather alternative has already found its way into the interior upholstery of major airline fleets, and many bus and coach operators. The unique material has been adopted by leading retail brands for footwear, as well as establishing itself as the eco-friendly material of choice for leather goods and both domestic and commercial upholstery.

ELFA Leather ECOLOGICALLY SOUND clean tech manufactureEvery part of ELFA Leather`s production is set out to minimise resources. From sustainable sourcing through to closed loop manufacturing and waste reduction during cut and sew operations.

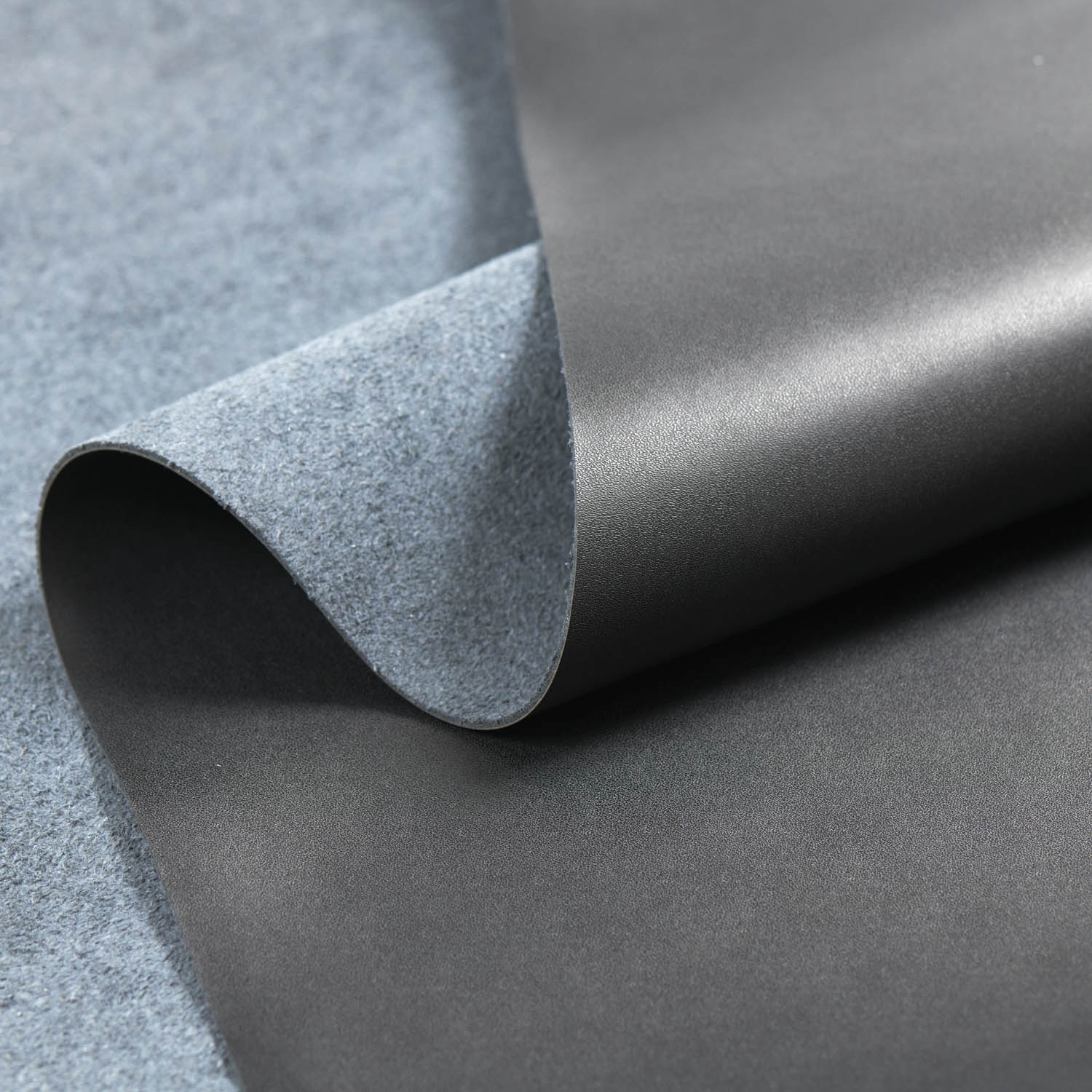

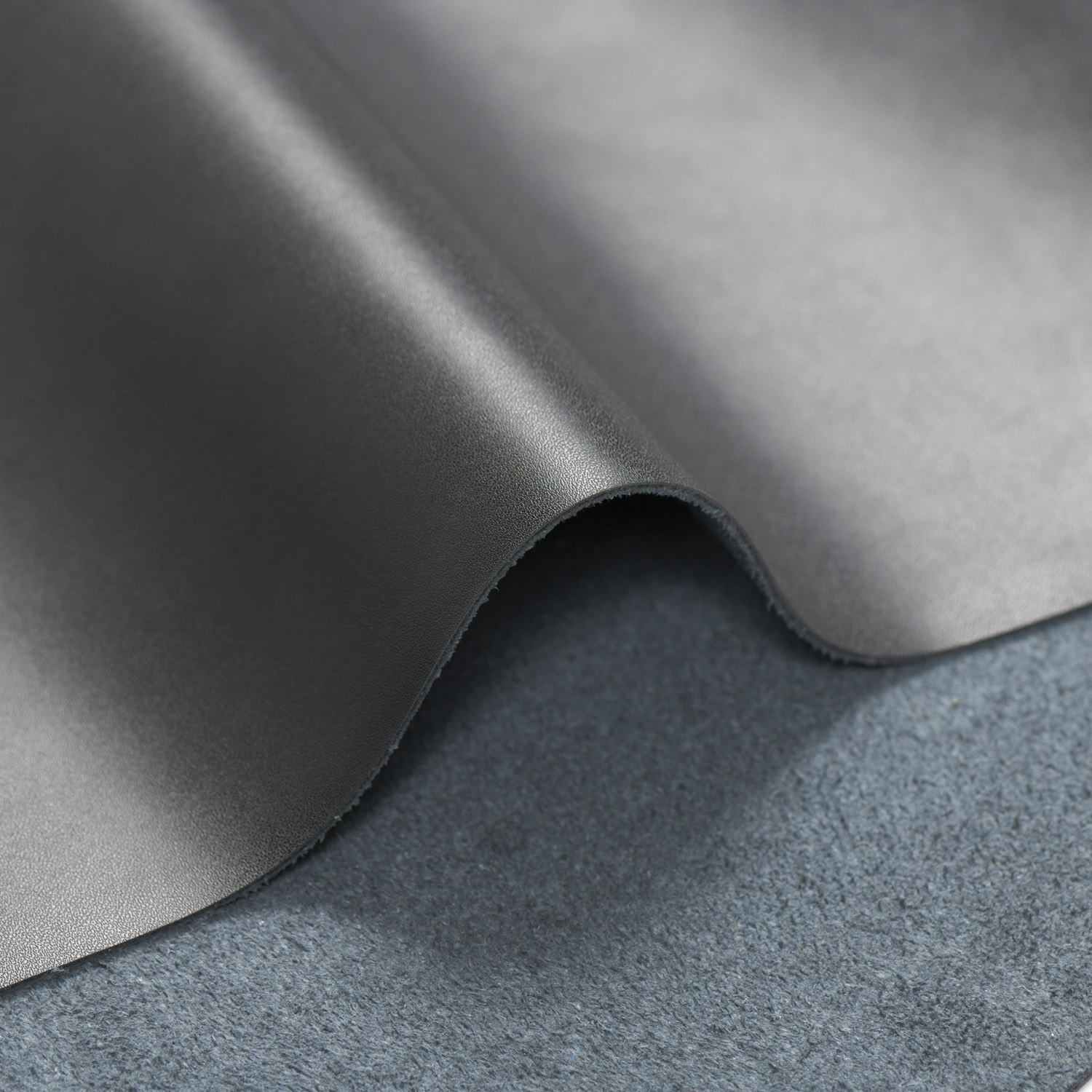

ELFA Leather`s unique patented process employs high-pressure water jets to force the recycled leather fibres through an integral textile reinforcement core.It`s a process that has major environmental advantages over conventional bonded leather, as it uses no chemicals. Its process is a continuous closed-looped system with 95% of water recycled.

ELFA Leather is available to cut from a roll 1.4m wide (55″), significantly saving on wastage compared to hides. With its automated stack cutting ELFA Leather also provides faster processing with up to 90% cutting yields. ELFA Leather allows for bespoke production. Its methods are able to be adapted to the specific performance requirements of each industry sector and the precise user application: whether it is hand sewing by highly skilled operatives, computer controlled multi-layer cutting or highly automated manufacture.

Leather and the Environment

Waste not, want not

The leather industry as a whole is responsible for generating huge amounts of waste as a by-product of its production. Take a tonne weight of hide, for instance, used to produce traditional leather.One ton generates up to 255kg of finished, tanned leather but almost three-quarters of a tonne is classed as waste. Meanwhile, harmful oil-based chemicals are used in the creation of bonded leather. However there is a corner of the industry that is geared to forging a more ecologically responsible method of leather production at every stage.

Recycled leather:

Saving waste and resources every step of the way

A leading supplier of recycled leather, ELFA Leather , has pioneered an environmentally friendly leather fibre material that has already made its way into many everyday products and applications, from airline seats to shoes. It takes off-cuts, shavings and trimmings, which are usually discarded by tanneries and would otherwise go to landfill, and recycles them to make its composition leather, ELFA Leather.

No chemicals needed

Another crucial difference between these methods and those employed by manufacturers of conventional bonded leather is that no chemicals are used whatsoever in the process of bonding the leather fibres together to form a sheet of material. Just use water alone.

Using a high-pressure water jet process has major environmental advantages. The supplier`s carbon footprint is dramatically reduced as a result because there are no oil-based adhesives present in the process. ELFA Leather, for instance, produces no harmful wastewaters in the manufacture of its composition leather. Their process is a continuous closed-looped system, with 95% of all water produced used in production being recycled.

Saving energy

In addition, product emissions at the ELFA Leather,plant in the form of solvents are thermally oxidated and the energy generated fed back into the manufacturing process. Its thermal oxidiser has cut natural gas use by between 50-70%.What all of this means for many leading companies is that the production methods of composition leather manufacturers such as ELFA Leather are able to be perfectly aligned with their own eco initiatives in cutting waste and reducing their carbon footprint.

Summary of composition leather’s eco advantages

Up to 50% less CO2 emissions

Up to 95% recycled water in process

Up to 50%-70% natural gas usage

Less landfill

No adhesives in textile core

Cuts waste Highly durable Uniform finish Easy care Extensive design options Environmentally friendly