What is the meaning of recycled leather and how is it made ?

Recycled leather, also known as eco-leather or sustainable leather, is a man-made genuine leather material made from scraps of leather or leather fibers that have been processed and combined with other materials, such as polyester or polyurethane, to create a new material with a leather-like appearance and texture. The primary purpose of recycled leather is to provide an alternative to genuine leather, which is derived from animal skins, while also being more environmentally friendly.

The process of making recycled leather typically involves the following steps:

- Collection and sorting: Scraps of leather or leather fibers are collected from various sources, such as leather manufacturers, garment factories, and shoe factories. These scraps are then sorted by size, texture, and color to ensure that they are suitable for recycling.

- Cleaning and degreasing: The sorted scraps are cleaned and degreased to remove any dirt, oil, or other impurities that may be present. This process helps to ensure that the recycled leather is free of contaminants and has a consistent appearance.

- Grinding and shredding: The cleaned and degreased scraps are then ground or shredded into smaller particles to create a uniform material that can be easily processed.

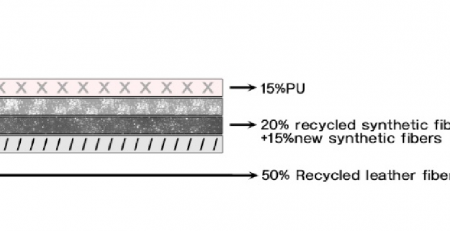

- Combining with other materials: The shredded leather particles are combined with other materials, such as polyester or polyurethane, to create a new material with a leather-like texture and appearance. The ratio of leather to other materials may vary depending on the desired properties of the final product.

- Forming and pressing: The combined material is then formed and pressed into sheets or other shapes, such as fibers or textiles, using heat and pressure. This process helps to bond the materials together and create a strong, durable material.

- Finishing and tanning: The formed material may undergo additional processing, such as tanning or dyeing, to enhance its appearance and texture. This may include adding pigments, dyes, or other chemicals to achieve the desired color and finish.

- Inspection and packaging: The final recycled leather product is inspected to ensure that it meets quality standards, and then it is packaged and prepared for shipping to manufacturers or retailers.

Overall, the process of making recycled leather involves converting scraps of leather or leather fibers into a new material that has a leather-like appearance and texture, while also being more environmentally friendly than genuine leather.